Round Bilge Hull With Full Length Chine

A simple variation of the round bilge hull theme

by Reinhard Siegel

Introduction

Modern racing yachts feature a single longitudinal chine. On some boats it runs from stem to stern, on others it is of partial length. According to the motto: what is right for a racer cannot be wrong for a cruiser, there are more and more boats with this hull form characteristic.

On the basis of the model sy15_full_chine.ms2 this article shows how to create a hull with a full length chine in MultiSurf. This is not about making a hull with specific dimensions, but shows which method is practical, so in the end you achieve what you intend.

Abbreviations used:

cp: control point (support point)

mc: master curve = support curve

In the following the terms used for point, curve and surface types are those of MultiSurf. This may serve the understanding and traceability.

The hull is derived from the model sy15.ms2, which was discussed in the article „On the Modeling of Round Bilge Hulls“.

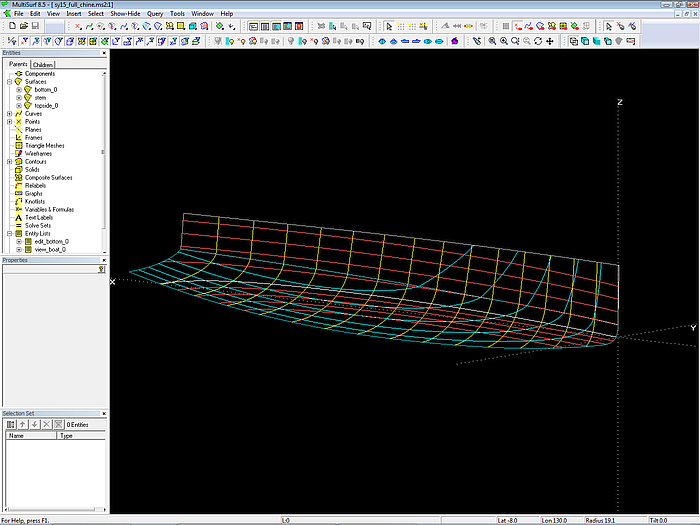

Model sy15_full_chine.ms2 opened in MultiSurf.

The hull is composed of 2 surfaces, one for the topside, one for the bottom. The topside is formed by a Developable Surface, the bottom is created as a C-spline Lofted Surface.

Why full length chine?

The decision to make the chine full length is a practical one. A gradually vanishing chine requires more skilled and precise craftmanship than a full length one. With metal hulls it is much easier to create a fair welded seam with a full length chine than achieve a neat vanishing knuckle.

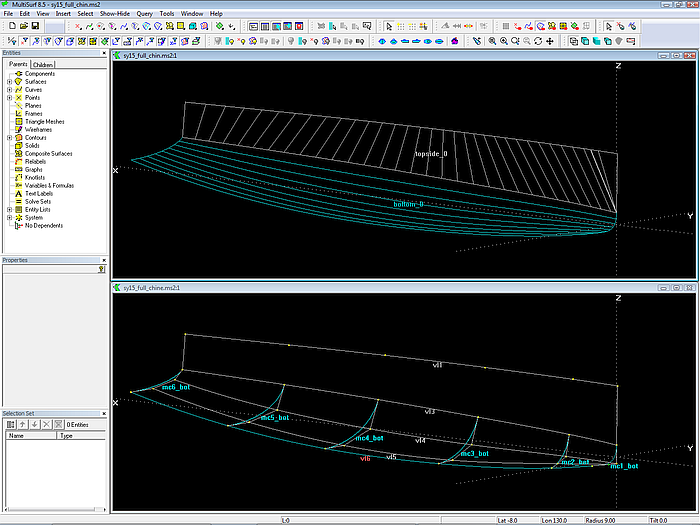

The topside is a Developable Surface spanned between the vertex curves vl1 and vl3.

A Developable Surface makes the topside, a C-spline Lofted Surface the bottom.

Why Developable Surface?

A Developable Surface is highly desirable for fabrication of metal boats, as bending of a flat sheet is such a simple operation compared with the in-plane stretching necessary to form compound curvature. [Quotation: MultiSurf Help]

A Developable Surface offers very little control on its cross section shape. It results from the arrangement of the rulings of the Developable Surface, which in turn depends only on the run of its parent curves.

If you need more influence on the section shape, the topside may also be a C-spline Lofted Surface. However, the ease of building is lost then.

Why C-spline Lofted Surface?

The explanations given in the article on the modeling of round bilge hulls by C-spline Lofted Surfaces is fully applicable here.

Note: if the hull shape leans to planking ⇒ C-spline Lofted Surface

The C-spline Lofted Surface for the bottom has 6 mcs. Each one is a B-spline Curve of degree 3 with 4 cps.

All the corresponding cps of the mcs are connected with C-spline Curves as vertex curves.

Why vertex curves?

Vertex curves are guiding curves for fairing a C-spline Lofted Surface. If we make them run in a harmonious, regular fashion, the surface is fair.

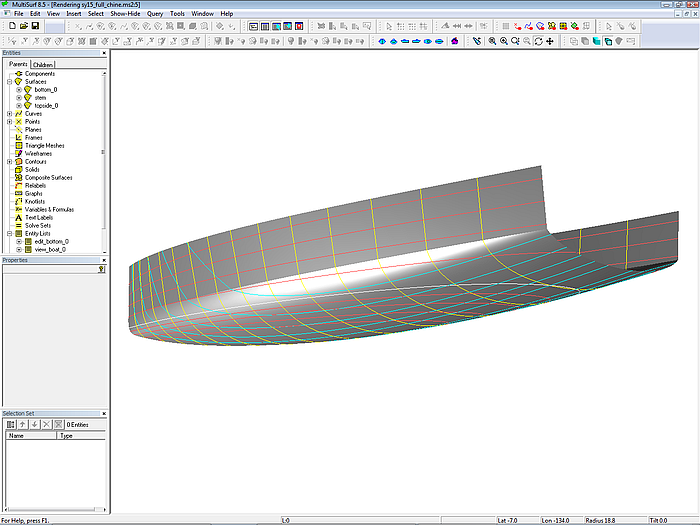

Render View of the model sy15_full_length_chine.ms2.

So we see, a round bilge hull with full length chine is a plain modification of the standard round bottom hull. If we can model a fair round bilge hull we can do one with full length chine as well.

However, a vanishing chine will be more demanding. See the next article.