MultiSurf Workshop Hoorn 2015

compiled by Reinhard Siegel

Contents:

Selected Support Topics

- Bowround

- Pontoon vessel

- Multiple surfaces vs PolyCurve mcs

- Sprayrail – Solve Set

- Screen layout

Selected Support Topics

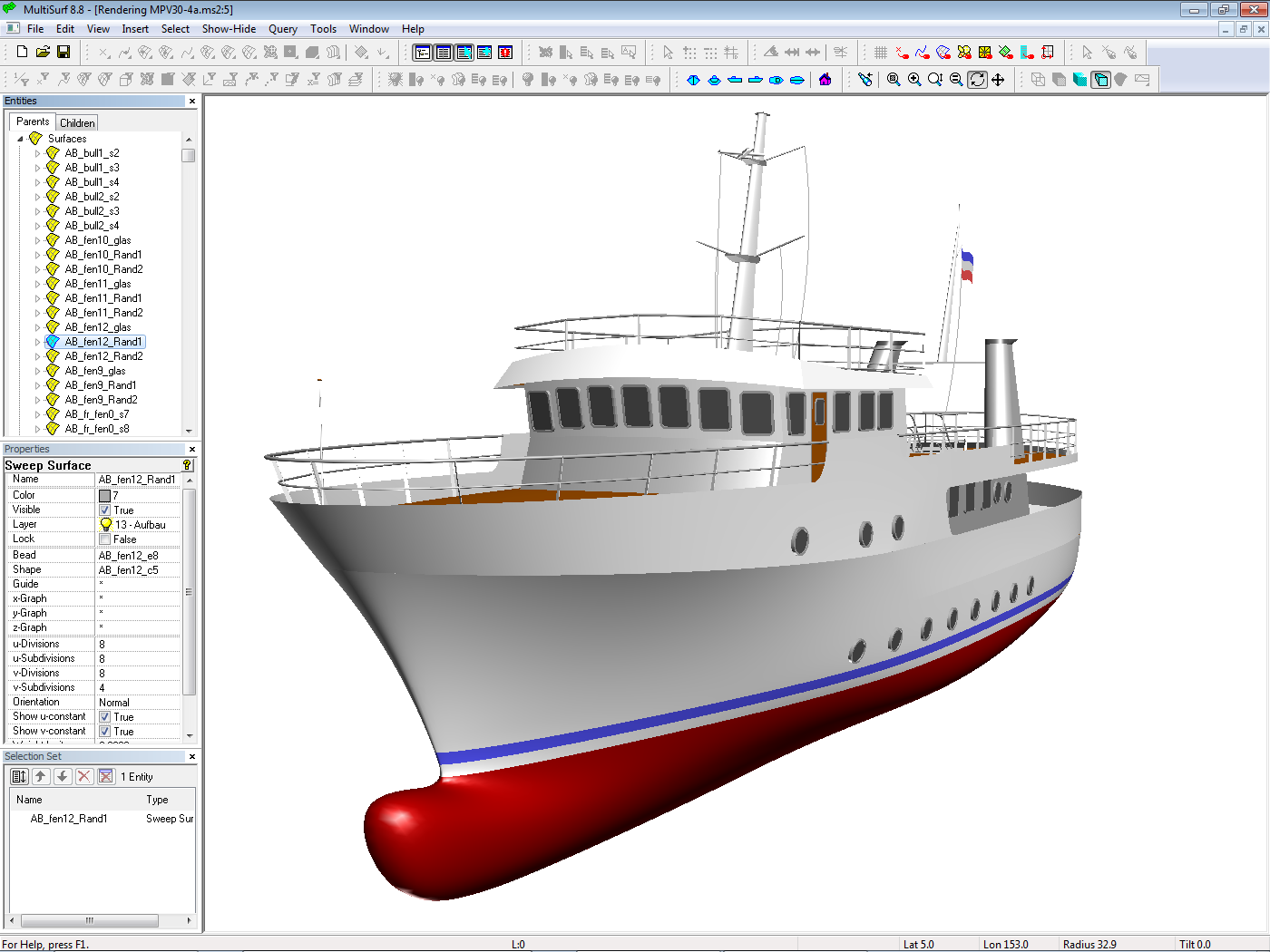

Bowround

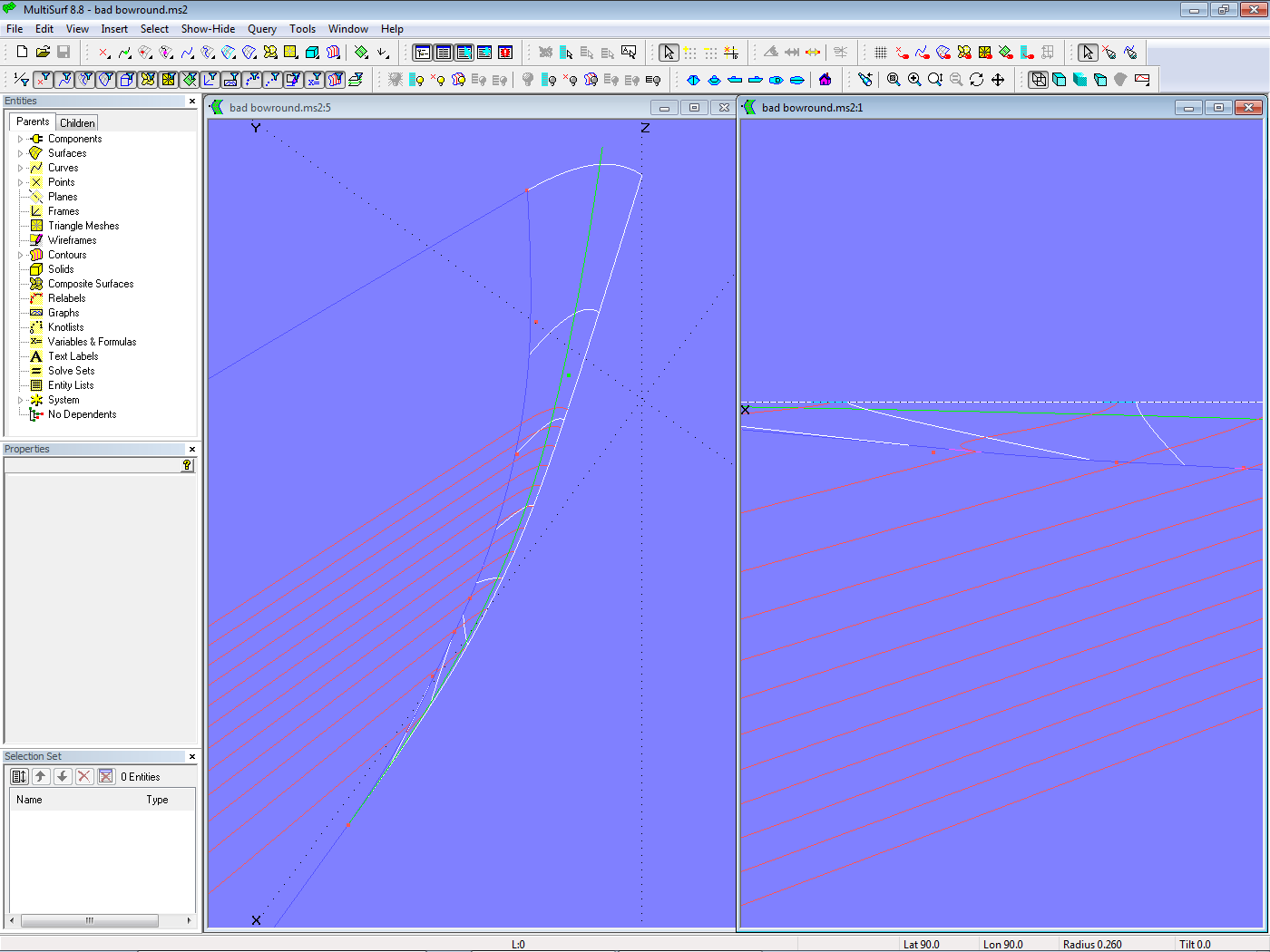

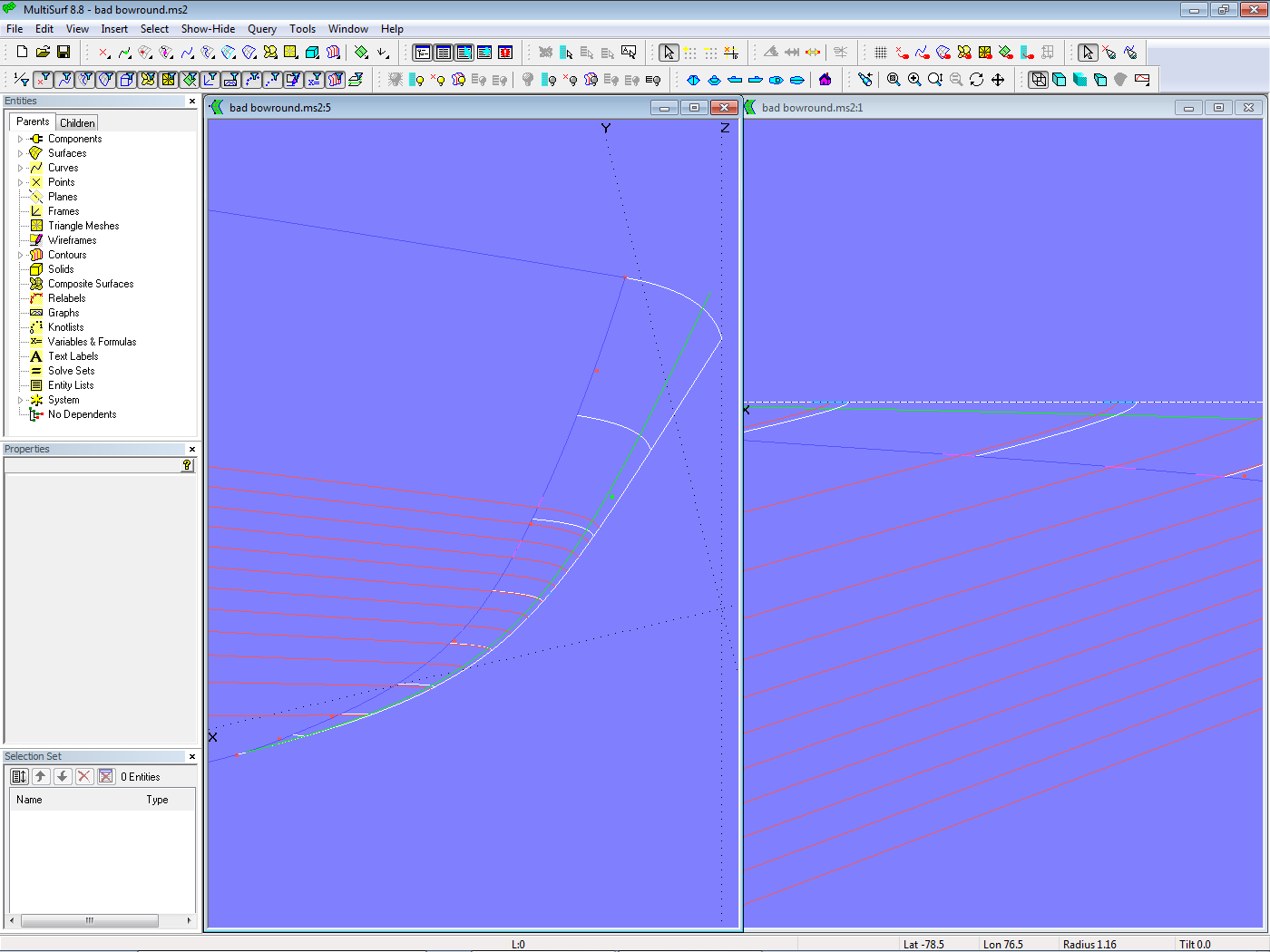

The model bad_bowround.ms2 shows wrinkles in the lower waterlines. The bowround is a B-spline Lofted Surface supported by 3 mcs: mc1 is a snake on the hull surface defining the start, mc2 is the stem mc of the hull surface, and mc3 is the projection of mc2 on the centerplane. Quite a standard construction.

Unsimilar t-parameter distribution of bowround snake mc causes distorted waterlines.

The distorted waterlines are caused by the very oblique run of the u-constant parameter curves in the forefoot. The t-parameter distribution of the snake is unsimilar to that one of the stem mc.

Moving the lower magnets of the snake mc makes the t-parameter distribution similar to that one of mc2.

Move its lower support magnets in order to change the t-parameter distribution of the snake. Then the waterlines will run normal. (Model corrected_bowround.ms2)

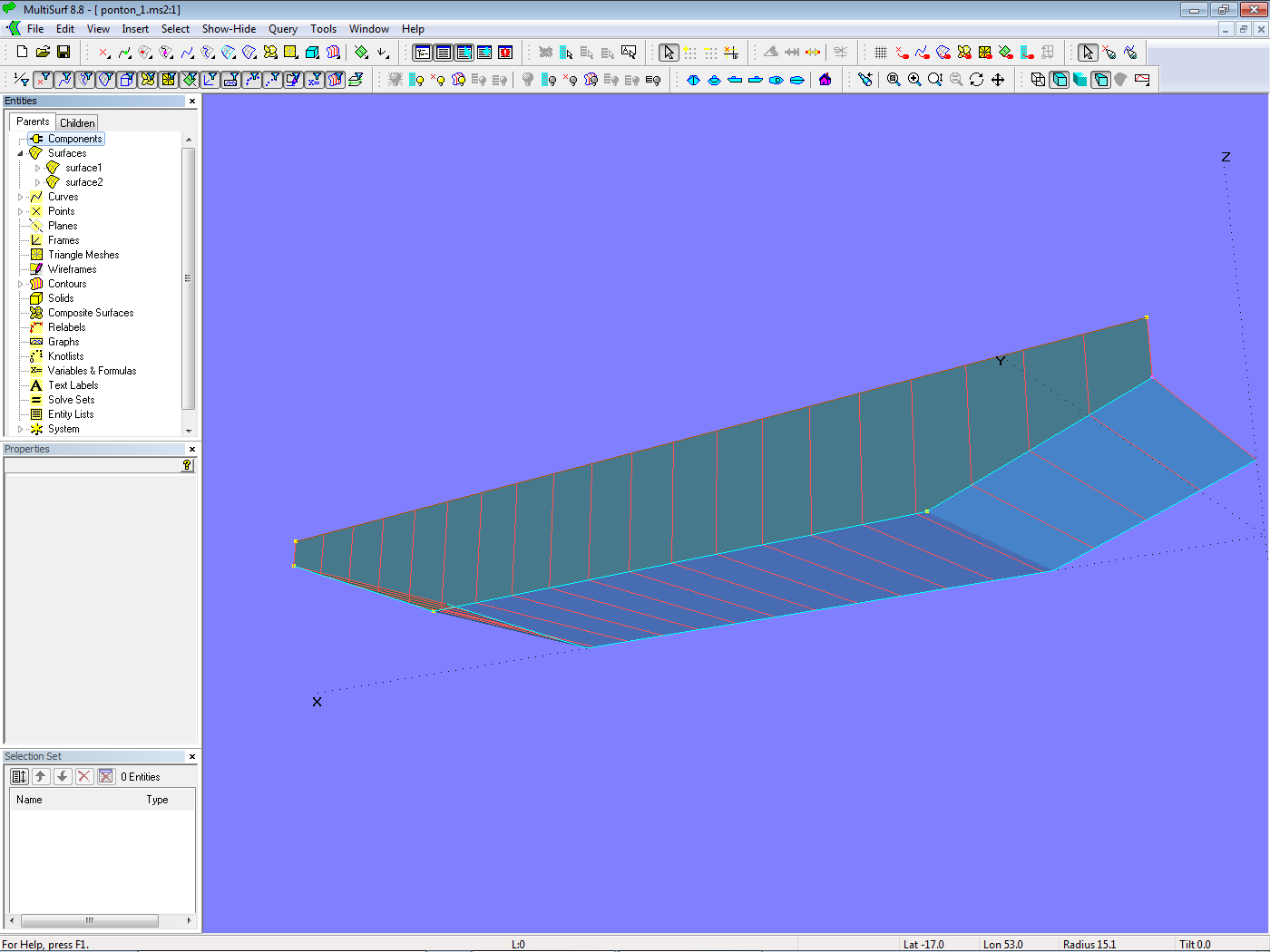

Pontoon vessel

Model ponton.ms2 shows an ordinary pontoon-like vessel. It is composed of 13 surfaces.

Pontoon constructed by 13 surfaces

The specific shape (vertical sides, stem, stern and flat deck and bottom) and the bilateral symmetry lean towards an easier construction.

Ponton_1.ms2: 2 surface in total

Multiple surfaces vs PolyCurve mcs

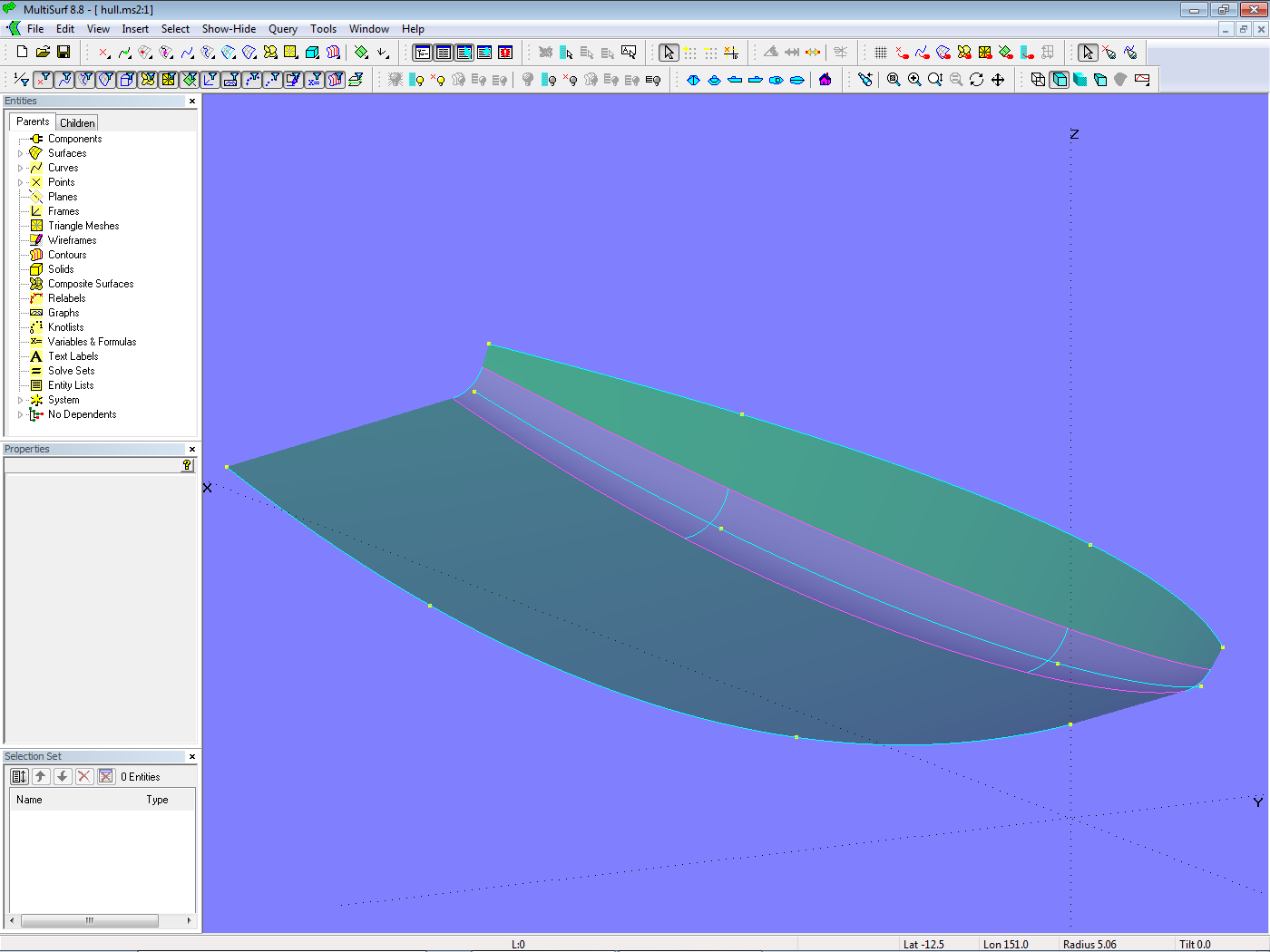

The model hull.ms2 shows 3 longitudinal surface strips. Surface1 (side) and surface3 (bottom) are Ruled Surfaces, while surface2 (bilge) is a C-spline Lofted Surface defined by 4 transverse Radius Arc mcs. Rounding off bow or stern will be more complex than with a single surface.

Model hull.ms2: 3 longitudinal surface strips

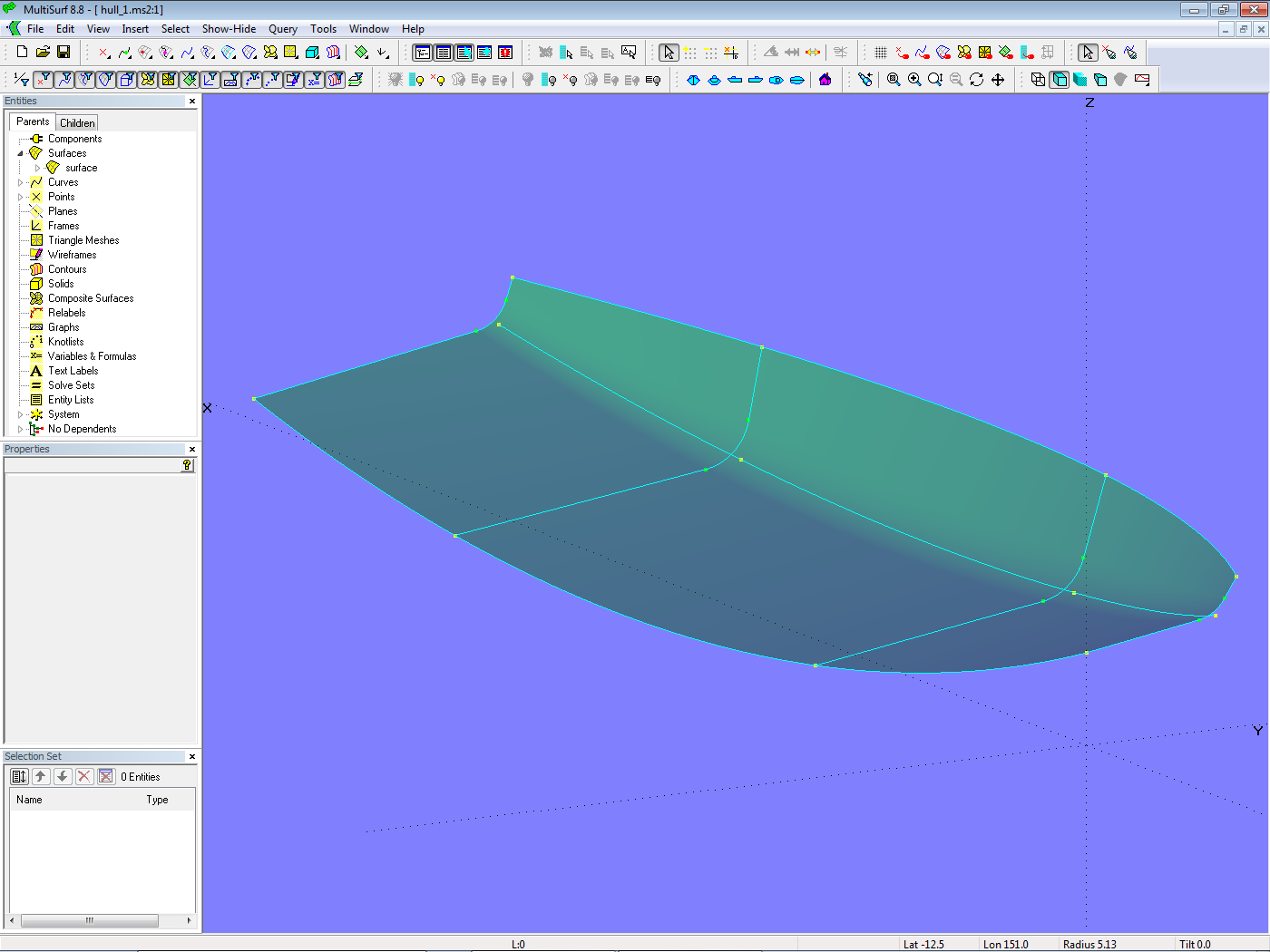

Model hull_1.ms2: single surface; transverse mcs by PolyCurves

Sprayrail - Solveset

How can an angle-iron be attached to a surface, so that both free edges will touch the surface? This is a geometry problem which cannot be solved directly. However, using MultiSurf´s Solve Set entity the construction is possible. Here are the steps to take:

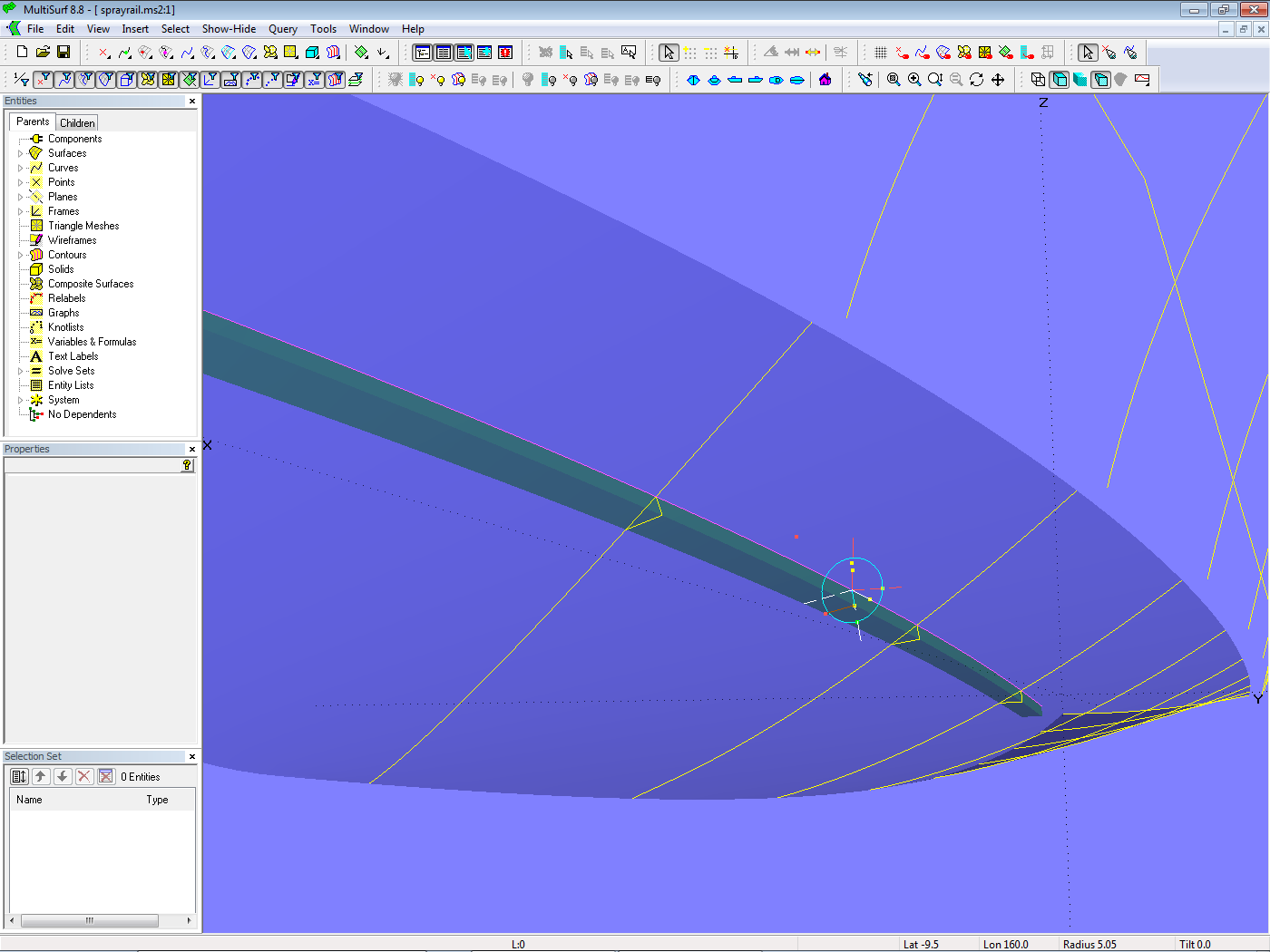

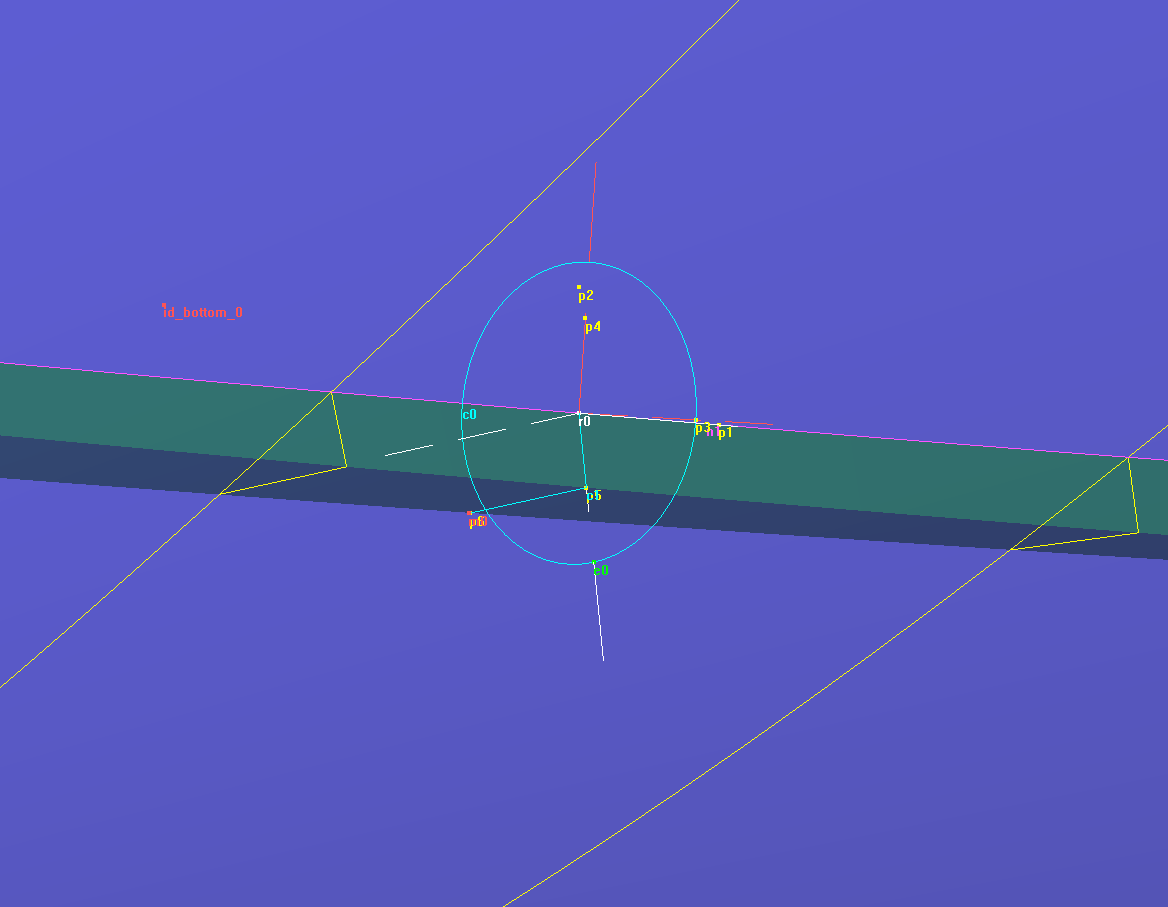

Model sprayrail.ms2: how to make the free edges of an angle-iron touch a surface

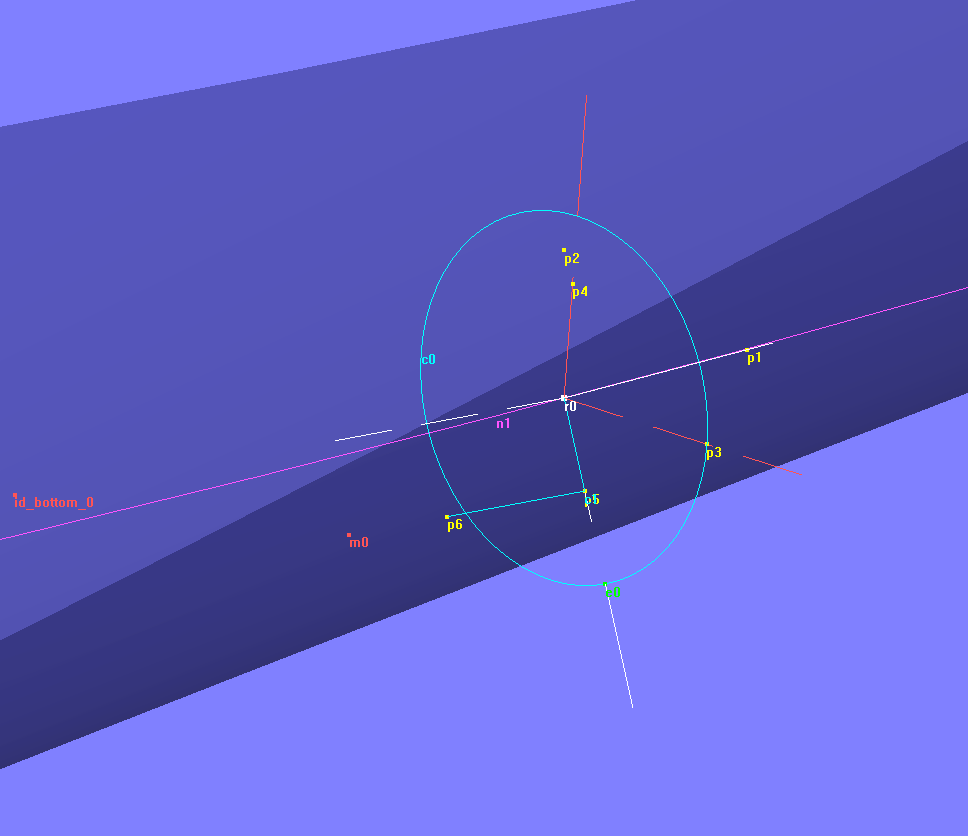

Create snake n1 on the surface to define the run of the spraychine.

Put Ring r0 on the snake.

Create Tangent Point p1 at the position of Ring r0.

Insert Point p2 based on r0 with dx = 0, dy= 0, so p2 is vertical above the ring.

Create 3-point Frame F1 using the ring as Point1, the tangent point as Point2 and the point as Point3.

Based on Frame1 create Point p3 with dx = 0, dy = 0.

Based on Frame F1 create Point p4 with dx = 0, dz = 0.

Define the Arc c0 using p3 as Point1, r0 as Point2 and p4 as Point3; type: 3. So we get a full circle laying in the YZ-plane of Frame F1 of its t-parameter until the distance of the magnet m0 to the plane a0 is zero. Now the angle-iron will touch the plating with both free edges.

The sprayrail itself is a Procedural Surface: Ring r0 is moved along the snake and the described construction is repeated for each t-position.

Insert Bead e0 on the Arc c0.

Create 3-point Frame F2 using Ring r0 as Point1, Tangent Point p1 as Point2 and Bead e0 as Point3. This frame rotates in the YZ-plane of Frame F1, depending on the location of e0.

Create points p5 and p6 based on Frame F2 with the dimensions of the angle-iron.

Make the cross section shape of the angle-iron as B-spline Curve c1, degree = 1, and control points r0, p5, p6. Moving the Bead e0 will rotate the shape.

Intersect the hull surface by curve c1 by inserting Intersection Magnet m0.

Create 2-point Plane a0 using p6 as Point1 and p5 as Point2.

Create Solve Set solve1 with supports e0, m0 and a0. The free entity is e0; the pair of constraints are magnet m0 and plane a0. Solve Set will change the location of the free entity (e0) by variation.

Construction details; Solve Set is dormant; the free end of the angle-iron (p6) is some distance off m0 (magnet on hull).

Solve Set active: the bead e0 is moved along the Arc c0 until the free end of the angle-iron touches the hull surface.

Welding an angle-iron to the hull plating is a cheap solution for a workboat.

Screen layout

The author prefers this screen layout (see image below):

no Manager Bar, no duplicate toolbar buttons, no Available Entities manager --> large drawing area

permanent open managers for Entities, Properties, Selection Set --> immediate information, direct access